EMJ Corporation has partnered with Branch Technology to build the world’s first 3D-printed house. EMJ will serve as the construction manager on record led by EMJ Special Projects and the EMJ Construction Technology department.

Branch Technology, a Chattanooga-based start-up, is home to the world’s largest free-form 3D printer and uses a technology called cellular fabrication, or C-FAB, to bring large-scale designs to life.

Founder and CEO Platt Boyd, who spent nearly two decades as an architect, developed the technology, which prints large structural shapes into cell-like matrixes for maximum strength, efficiency, and nearly limitless options—unlike traditional construction materials and/or designs that were once impossible to actually construct.

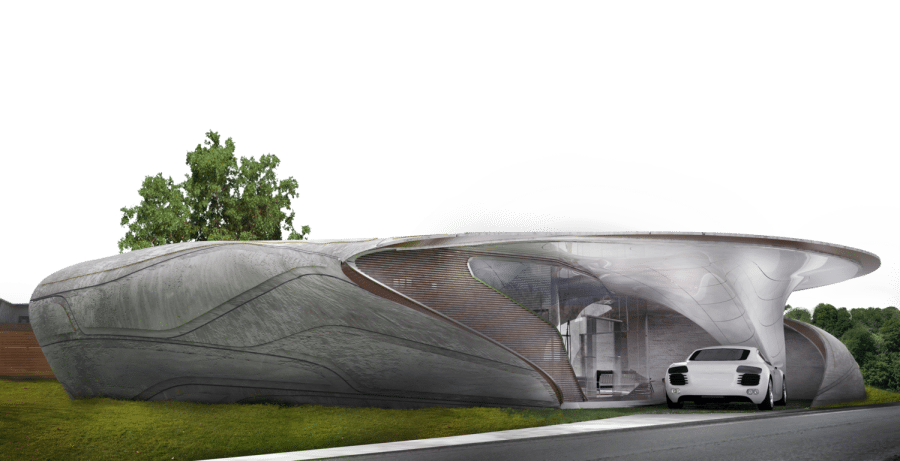

Branch gained national coverage when it announced its sponsorship of a design competition to construct the first 3D-printed house through its new technology. After reviewing submissions from 1,300 designers in 97 countries, Branch awarded WATG in Chicago with the winning design for its 1,000-square-foot, 1-bedroom, 1-bathroom house entitled “Curve Appeal.”

Printing and building a house piece-by-piece is unprecedented, but Branch has already tackled similar projects across the nation, including being involved in the world’s largest 3D-printed pavilion and the design for a 3D-printed habitat for NASA’s deep space exploration. Similarly, the house will be created by printed carbon fiber polymer matrixes, which will be filled with traditional insulation and then clad with dry wall.

“Branch is a world-class leader in bringing innovation to the construction industry,” says Jonathan Deming, Director of BIM and Construction Technology at EMJ. “This work has the potential to completely revolutionize the architecture, engineering and construction industries.”

Branch and EMJ are currently collaborating on the final plans for the house. This includes site logistics planning, phasing of prefabrication and installation, constructability and engineering of the design components.

“We are testing materials, mocking up options and reviewing scenarios to ensure the house is built to the highest quality standards,” said Jonathan Horne, EMJ Director of Quality, who is working alongside the EMJ Special Projects team and the Construction Technology Department to finalize the construction plans.

The house is expected to be completed in 2018 and will be built on the Chattanooga State main campus to be later used as an advanced technology demonstration space.

To learn more about plans for the 3D-printed house, click here, and see more about Branch’s C-FAB technology here.

Related articles:

Big ideas: 3D printing pioneer Branch Technology ‘doing things no one else is doing’

Behold: The World’s First Freeform 3D-Printed House Might Look Like This

See the Designs for the First Free-Form 3D-Printed House