Earlier this year, EMJ completed an expansion at Ruby Falls, a tourist attraction in Lookout Mountain, Tenn., that boasts the nation’s largest public underground waterfall. Our team constructed a new lobby, retail space, pedestrian mall, and more next to the original, historic castle that sits more than 1,000 feet above the underground waterfall.

The expansion required removal of a significant amount of rock to create a pad for the new construction. Considering the site’s location on a mountainside above an underground cavern, the team carefully drilled out the rock section by section, rather than blasting. As documented in a recent Ground Up podcast, the rock removal process required precision planning, logistics, and execution by all project team members. It also required careful consideration for how to prepare the resulting site to endure the elements for many years to come.

Among those considerations was waterproofing and the best method to ensure the exposed rock could withstand the elements. Of particular concern was a void between the new building and the rock wall. This gap was created when the team carved out the rock to create the building pad. The design team presented two options for EMJ to consider: apply a vinyl-waterproofing product or fill the space between the building and the mountain with concrete.

But, here was the catch. While the team could estimate the cost of the vinyl waterproofing, it was impossible to measure the gap and estimate the cost of the concrete.

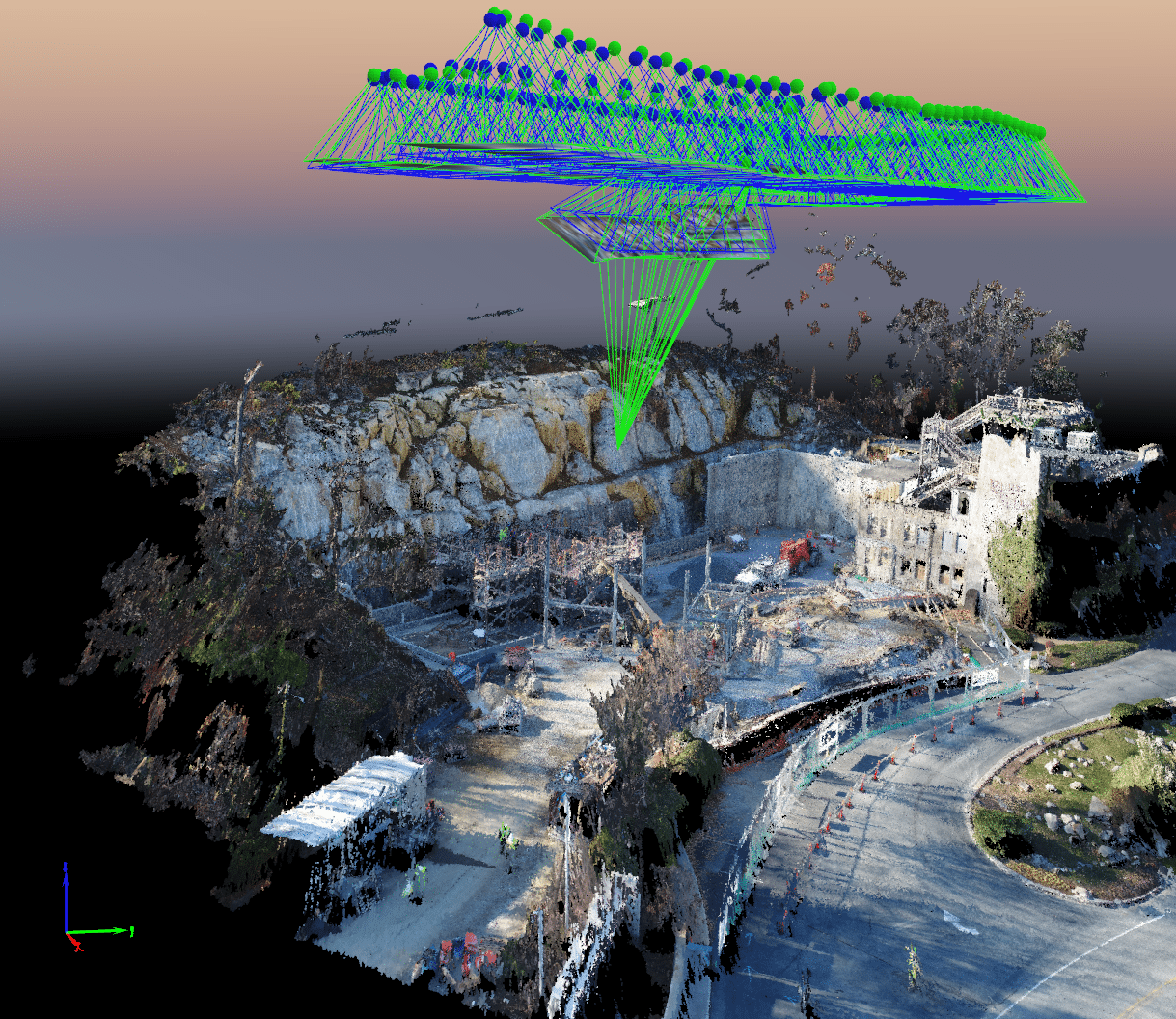

The team called on Caleb Wickersham, EMJ Virtual Construction Engineer and licensed drone pilot, who had already flown the site and created a 3D model of the mountainside using photogrammetry.

Caleb layered the architect’s building model next to his mountainside model. Using his previous calculations, he was able to determine the volume of the space between the building and the mountain, which provided the amount of concrete needed to solve the waterproofing issue. From this, the team calculated the concrete cost, and in comparing it with the vinyl-waterproofing cost, the vinyl product was the more cost-effective and prudent option for Ruby Falls.

There is an old adage that applies to construction, “Measure twice and cut once.” In a figurative sense that means to plan and prepare in a careful, thorough manner before taking action. Using construction technology, that is exactly what the Ruby Falls team did, helping make sure its recommendation to the client was accurate.

Check out this video of Caleb’s handywork.

Related story: