The structural concrete slab of the Wegmans grocery store in Medford, Mass., includes several recessed areas, trench drains and a significant amount of utilities running through and below it.

Realizing the room for error in the complicated design, Boston’s EMJ Construction team reached out to Will Callery, Virtual Construction Engineer, and Brian Tiehen, Quality Manager, for assistance in planning their approach.

Together, the teams reviewed the plans and set up a measurably accurate 3D model of the slab penetrations, elevations and specialty features. The model provided the project team with a map to identify each slab’s dimensions and where each feature on the slab should be located.

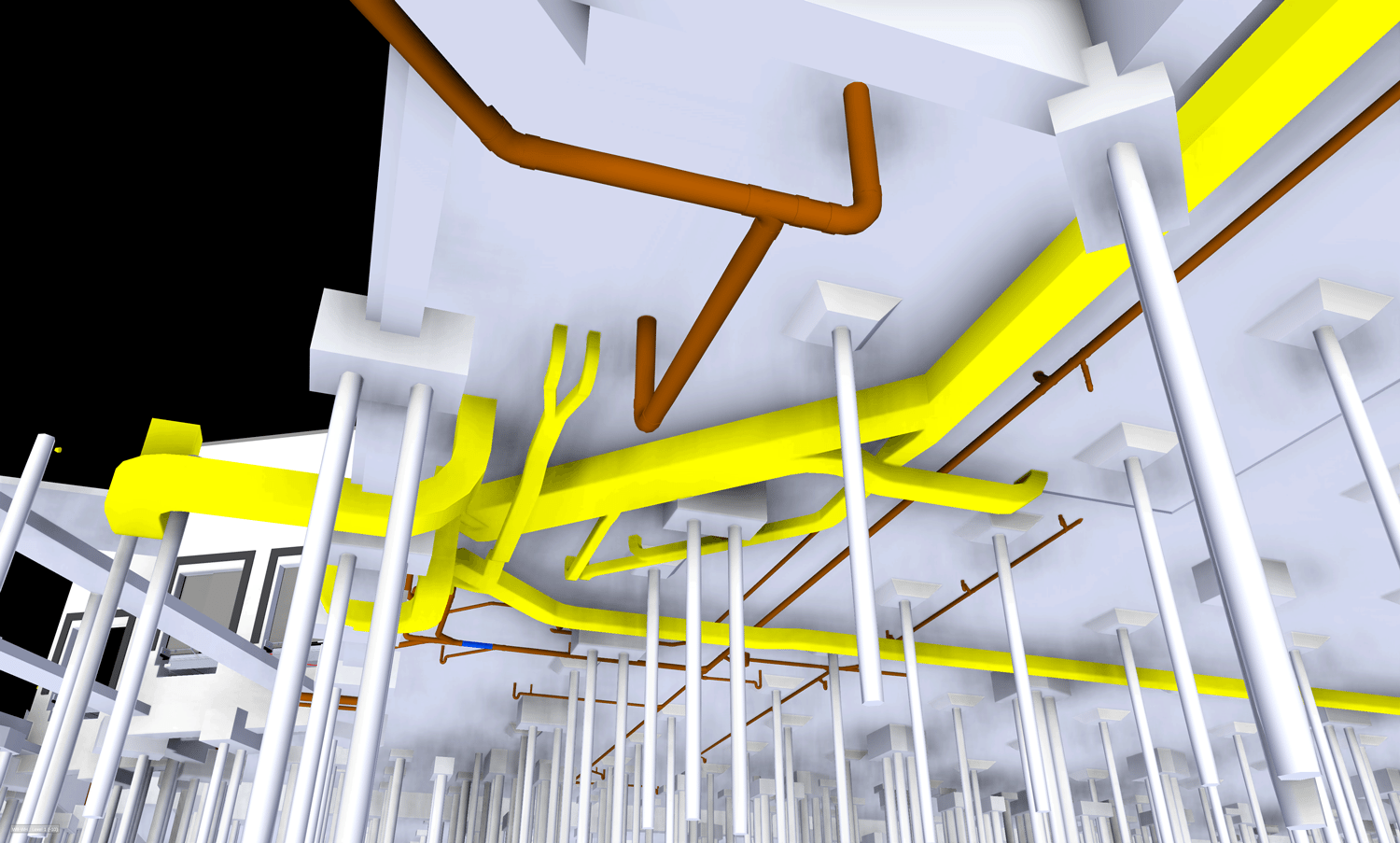

Underslab BIM Coordination showing sanitary and electrical slab penetration locations. This process was used to locate slab penetrations and avoid conflicts.

For example, it could be used to see how the drain locations aligned with owner provided equipment or to make sure an electrical box didn’t get placed directly under a wall.

“The team knew exactly what we were going to be working with before we even got started, and the technology helped identify potential problem areas and prepare adequately,” said Bruce Tassone, Senior Project Manager. “It helped ensure proper placement and prevent clashes.”

Photo courtesy of Wegmans, www.wegmans.com

The Medford Wegmans is on track for a fall opening.

Read more about the team’s outstanding work on the project in this article about using templates to perfect drywall details.

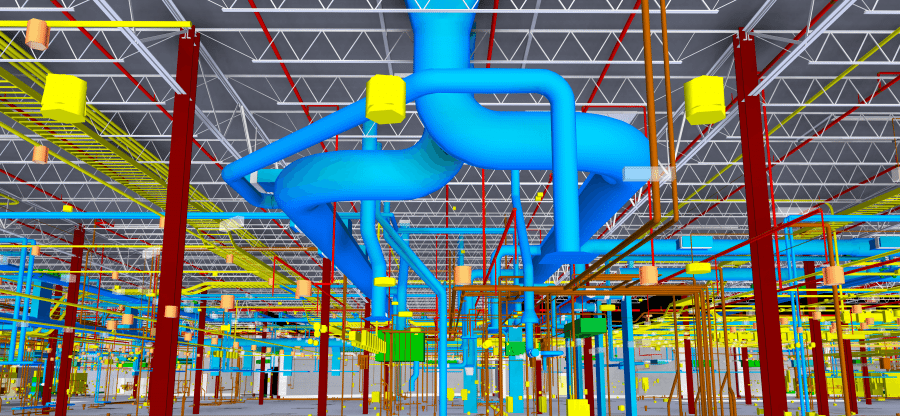

Snapshot of the overall BIM coordination, showing multiple trades represented in 3D.